Flow Simulation

Solidworks 3D Design

Consulting on Specifications and Tolerancing

Extensive Knowledge of Mechanical Assembly

Prototyping Services

We supply industries and OEMs across the board, from medical to construction to furniture to hardware.

Tired of high minimum run and order quantities? At Gupta, we see low quantity runs as an integral part of our business. Getting up to 1,000 lbs (a popular industry minimum) per order can often be difficult, especially for light, streamlined profiles. At Gupta, we are glad to set up and push whatever quantity your demand dictates.

In terms of units, even programs of 500 pcs/year or less can often be quoted and produced very competitively.

At Gupta, we consider our high level of expertise, technology, and experience an enormous competitive advantage.

And of course, nothing would be complete without our prompt, courteous customer service. Our goal is to be available and responsive and keep our customers in the know about the status of their orders. Our customers receive automated emails throughout the ordering process, from initial receipt to final shipment.

Let us go to work for you today!

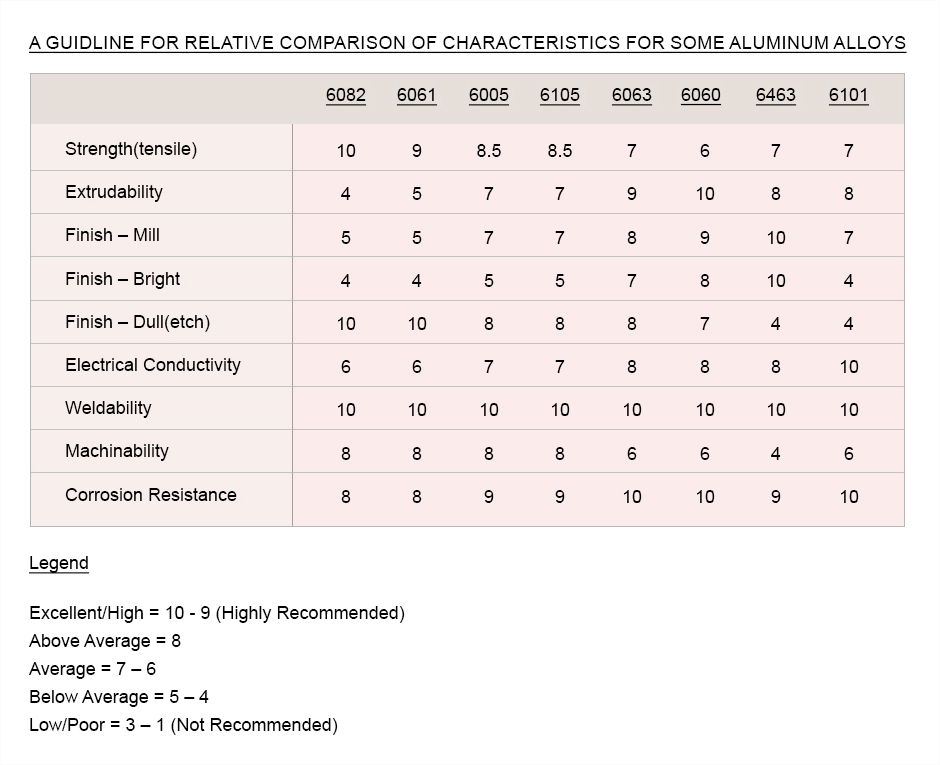

We offer a wide array of alloys to service any application you can think of, ranging from highly structural to critical aesthetics. In addition to the more common alloys listed below, Gupta can often supply other materials upon request.

In addition to the above 6XXX series alloys, we also can extrude alloys 1100 and 1350, which are high-purity aluminum alloys (>99% aluminum). Special precautions should be taken when designing with these types of materials. Contact us for details.

Press sizes range from the very small to more than 10”, capable of pushing upwards of 12 lbs/ft.

For channels, hollows, and solid profiles, a wide variety of press sizes and tonnages are available to push your profile in a cost effective manner.

Factors such as weight/foot, maximum inscribed circle size, and profile shape (channel, hollow, or solid) will respectively determine press size and minimum run requirements. This being said, runs below the common minimum of 1000 lbs are oftentimes not a problem. This may or may not be true for larger sized profiles, so we encourage you to send us your designs for review.

Supplying extrusions complete with secondary machining IS our specialty. From a few tapped holes to deep multi-axis contouring, there is no application beyond our expertise. Furthermore, our precision cut-off saw can hold extremely tight tolerances, often eliminating the need to machine these surfaces. This cuts the number of setups, reduces cycle time, and reduces cost for the customer.

For general fabricated weldments involving extrusions, we operate a welding department with highly skilled non-ferrous welders. Our certified welders can perform MIG, TIG, ARC, brazing, and other metal-joining processes to suit your needs.